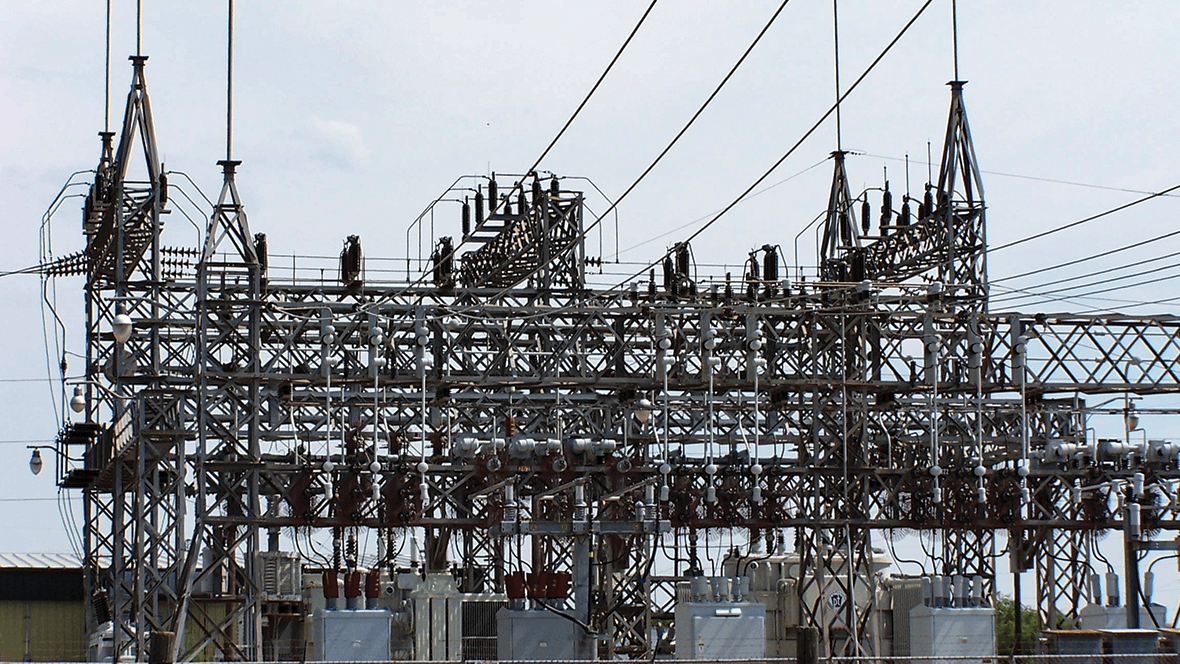

Regular temperature monitoring of your substation components can help you both inspect and diagnose impending failures before they occur. Using a thermal camera, you can easily scan for temperature differences and hot spots to locate the problem area and diagnose the issue. You’ll establish a safer work environment, increase product efficiency across the system, and improve customer satisfaction by ensuring no loss of electricity.

Regular temperature monitoring of your substation components can help you both inspect and diagnose impending failures before they occur. Using a thermal camera, you can easily scan for temperature differences and hot spots to locate the problem area and diagnose the issue. You’ll establish a safer work environment, increase product efficiency across the system, and improve customer satisfaction by ensuring no loss of electricity.

Regular temperature monitoring of your substation components can help you both inspect and diagnose impending failures before they occur. Using a thermal camera, you can easily scan for temperature differences and hot spots to locate the problem area and diagnose the issue. You’ll establish a safer work environment, increase product efficiency across the system, and improve customer satisfaction by ensuring no loss of electricity.

Regular temperature monitoring of your substation components can help you both inspect and diagnose impending failures before they occur. Using a thermal camera, you can easily scan for temperature differences and hot spots to locate the problem area and diagnose the issue. You’ll establish a safer work environment, increase product efficiency across the system, and improve customer satisfaction by ensuring no loss of electricity.

Recommended Models: