Vibration Analysis Inspections incorporated into WEBCOR; Bringing all your Condition Based Monitoring practices into one WEB based Portal.

Vibration Analysis is primarily utilised on rotating equipment in order to identify excessive repetitive or cyclical movement.

There are three basic vibration characteristics;

Amplitude: This is the ‘Back and Forth’ motion found on rotating equipment which can be described as cyclical, repetitive and vibration and is the unit utilised to measure the size of this movement.

Frequency: This unit is used to identify how often the motion occurs. It is directly related to the RPM of a machine.

Phase Characteristics: This offers the direction of the movement during the vibration cycle and provides valuable information when determining how the movements of different parts of the machine are relating to each other.

Measuring Vibration: There are three commonly used sensors which measure vibration characteristics and these are known as transducers.

Accelerometer:- Rugged, compact and light weight with a wide frequency range designed for machine casings which provide sensing of absolute case motion in terms of acceleration.

Velocity Transducer:- This contains a magnet surrounded by a coil suspended between a spring and damper and produces electricity proportional to the velocity of the mass and are usually mounted on bearing housings.

Displacement:- These are mainly utilised for measuring the displacement and vibration on the rotating shaft of the machinery.

Analysis and Trending:

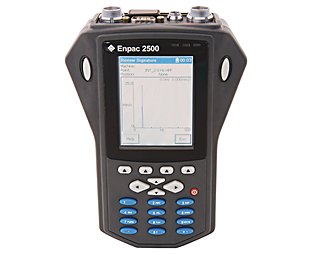

We utilise Rockwell Enpac Data Collectors and input specific data and field values into our TICOR software whilst in the field. This allows us to trend data between periodic inspections to pinput differences and also highlight faults found with root cause and potential remedial recommendations. Reports are produced immediately and uploaded into WEBCOR for data management and fast distribution of results to responsible personnel.